close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-05-16 Origin: Site

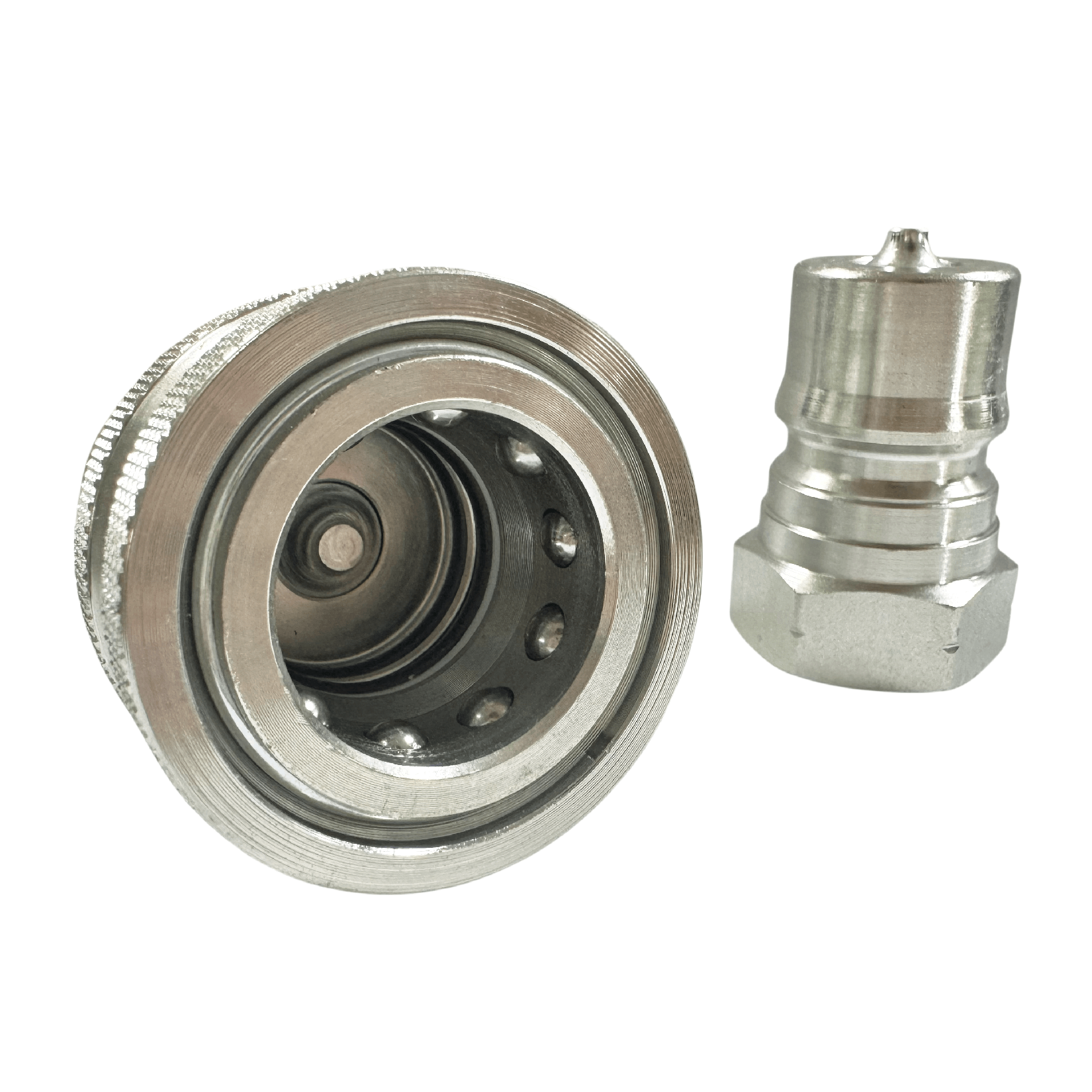

In many industries and applications, quick couplings have revolutionized the way connections are made and changed. Whether it’s for hydraulic systems, pneumatic tools, or water hoses, quick coupling connectors provide a fast, secure, and efficient solution that minimizes downtime and simplifies operations. If you’re new to using quick couplers or looking to improve your setup, this guide offers detailed insights and practical steps for safe and effective use, including installation, safety tips, and benefits.

This article covers everything from basic preparation and safety to detailed installation processes for both industrial equipment and golf course watering systems. We will also explore the various types of hydraulic quick coupling, pneumatic quick coupling, and specialized standards like American, European, French, and Japanese standard quick couplings to help you choose the right product for your needs.

Safety should always be your top priority when handling quick release coupling systems, especially in hydraulic or pneumatic applications. Improper installation or misuse can lead to equipment failure, leaks, or even accidents. Here are essential safety practices to keep in mind:

Always depressurize the system before disconnecting or connecting a quick disconncet coupling.

Use a quick coupling valve key where applicable to avoid hand injuries and ensure proper locking.

Wear protective gear like gloves and safety glasses to shield from unexpected fluid release.

Confirm compatibility between coupler types and hydraulic hoses, ensuring the hydraulic quick coupling types match your equipment.

Inspect all components for wear or damage before installation.

Before starting any work on installing a hydraulic quick coupling, it’s critical to prepare your workspace and personnel for a safe operation:

Shut down and lock out the machinery to prevent accidental startups.

Relieve any residual pressure in hydraulic or pneumatic lines.

Confirm that the working area is clean, dry, and free from obstacles.

Have an emergency plan in place in case of leaks or spills.

Successful installation requires the right tools. Common essentials include:

Adjustable wrenches and spanners

Screwdrivers for securing clamps or fittings

A quick coupling valve key for locking and unlocking the coupler safely

Thread seal tape (like Teflon tape) to ensure leak-free connections

Cleaning cloths and degreasers

There are many types of quick couplers designed for different applications—be it for fluid transport applications such as in injection molding machines or die casting machine molds, or for use in heavy mechanical equipment. Before installation, study the specifications carefully:

| Standard Type | Common Applications | Notable Features |

|---|---|---|

| American standard quick coupling | Construction & hydraulic machinery | Robust, widely compatible |

| European standard quick coupling | Industrial fluid systems | High precision, good sealing properties |

| French standard quick coupling | Agriculture and irrigation | Compact design, easy to operate |

| Japanese standard quick coupling | Pneumatic tools and machinery | High durability, vibration resistant |

This understanding helps avoid mismatches and ensures long-term reliability.

When upgrading your machinery with a hydraulic quick coupling, positioning your excavator or equipment correctly is crucial for safe removal of the old attachment:

Park on stable, level ground.

Engage parking brakes and ensure the machine is off.

Lower attachments gently to the ground to relieve stress on hydraulic lines.

Hydraulic lines must be disconnected without causing leaks or contamination:

Use the quick coupling valve key if your couplings have locking mechanisms.

Slowly loosen connections to release residual pressure.

Cap the ends of hydraulic lines to prevent dirt ingress.

Once the lines are disconnected, unbolt or unlatch the attachment carefully. Avoid sudden drops or impacts, which can damage the equipment or cause injury.

Install the new hydraulic quick coupling assembly according to manufacturer instructions. Typically:

Align the coupler precisely with mounting points.

Secure it firmly with bolts or pins to avoid movement.

Confirm that locking mechanisms operate smoothly.

Attach hydraulic lines to the quick coupler:

Use proper fittings compatible with your quick coupling connector.

Apply thread seal tape to ensure leak-proof joints.

Use the quick coupling valve key for a secure lock.

After everything is connected:

Repressurize the system slowly.

Check for leaks or unusual noises.

Operate the attachment through its full range to ensure smooth connection and disconnection.

If leaks are found, shut down and tighten connections.

If you manage a golf course, installing a quick coupling for water hose can save time and effort when watering greens or landscaped areas. Here’s a step-by-step guide:

Prepare:

Quick coupler assembly suitable for garden hoses

Hose clamps

Teflon tape

Screwdriver and wrench

Garden hose

Choose an accessible, flat area near your water source where the coupler will be installed.

Clear debris and level the ground. Make sure the water supply line is off before starting.

Attach the quick coupler to the water source pipe or spigot, following the product’s instructions.

Securely connect the water supply line to the coupler’s inlet side.

Wrap Teflon tape around threaded ends to prevent leaks.

Connect your garden hose to the coupler’s outlet using clamps to ensure a firm fit.

Turn on the water supply and check for leaks or pressure drops.

Install a protective cover over the coupler to shield it from damage and dirt.

Ensure all users know how to connect and disconnect the quick coupling properly.

Quick couplings offer numerous benefits across industries:

Time-saving: Rapid connection and disconnection minimize downtime.

Safety: Eliminates the need for tools or manual threading, reducing injury risks.

Versatility: Compatible with hydraulic, pneumatic, and water hose systems.

Leak Prevention: Properly installed quick couplings maintain a tight seal.

Durability: Designed for repeated use in tough environments.

Standardization: Available in multiple standards like American, European, French, and Japanese, ensuring worldwide compatibility.

For those interested in premium hydraulic quick coupling products, including quick release coupling systems suitable for fluid transport or mechanical equipment, visit the trusted source at Tianying-Quick Coupling. They offer a broad range of quick coupling hose connection solutions for industrial, agricultural, and commercial use.

When you add new tools or attachments, always confirm compatibility with your existing hydraulic quick coupling types and standards. Proper installation ensures smooth start-up operation and prevents damage to your injection molding machines or die casting machine molds.

Whether you’re upgrading heavy machinery with hydraulic quick coupling systems or improving irrigation efficiency with quick coupling for water hose setups, mastering the installation and maintenance of quick couplers is essential. With safety at the forefront and the right tools and knowledge, you can enjoy faster workflows, reduced downtime, and safer working conditions.

Q1: What is the main advantage of a hydraulic quick coupling over traditional fittings?

A1: Hydraulic quick couplings allow for fast, tool-free connection and disconnection, reducing downtime and minimizing fluid leakage risks.

Q2: Are quick couplings standardized across different countries?

A2: Yes, they follow standards like American, European, French, and Japanese, each with unique dimensions and features to ensure compatibility.

Q3: Can quick couplings be used for pneumatic systems?

A3: Absolutely. Pneumatic quick couplings are specifically designed for air pressure applications and offer similar ease of use.

Q4: How do I prevent leaks when connecting quick couplings?

A4: Use thread seal tape such as Teflon tape and ensure proper alignment and secure locking of the coupler.

Q5: Is a quick coupling suitable for golf course watering hoses?

A5: Yes, quick coupling for water hose systems make hose attachment and detachment fast and convenient, ideal for large turf irrigation.

Q6: What tools do I need for installing a hydraulic quick coupling?

A6: Basic tools include wrenches, screwdrivers, a quick coupling valve key, and thread seal tape for leak-proof connections.

By integrating the latest industry trends, safety guidelines, and practical steps, this comprehensive guide equips you with the knowledge to confidently use and install quick couplers for a wide range of applications. Whether in construction, manufacturing, or groundskeeping, quick couplings are a game-changer in operational efficiency and safety.