close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-06-19 Origin: Site

Choosing the right hydraulic coupling manufacturer affects how well systems work. It also affects how reliable they are. Different hydraulic systems need special solutions. Mobile hydraulics need to be small and strong. They also need to handle tough environments. Industrial hydraulics need to be quiet and work well all the time. Some hydraulic coupling manufacturers make products that do not leak. Their products are strong and safe. They help customers have less downtime. They also help systems work better.

Pick hydraulic coupling manufacturers that make good, dependable products. This helps your systems stay safe and work well.Find suppliers with key certifications like ISO. These show the products are safe, high-quality, and last a long time.Choose manufacturers who create new designs. They should also give good customer support for easy setup and care.Learn about the types of hydraulic couplings, like quick couplings and flat face couplings. This helps you pick what works best for you.Think about custom hydraulic couplings for special projects. These can fix special problems and help your system work better.

Picking the best hydraulic coupling suppliers takes careful thought. Companies need to make sure the hydraulic coupling fits their needs. They should check things like pressure rating, flow rate, and temperature. The material must work with the hydraulic fluids. This stops rust and helps hydraulic couplings last longer. The way the connection works is important too. Quick-disconnect couplings are good for changes that happen a lot. Threaded ones are better for setups that stay the same.

Looking at online reviews and what other people say can show if a supplier is good. Many buyers trust what they read online as much as what friends say. This shows that customer happiness is very important when picking hydraulic coupling suppliers.

Other things to think about are how easy it is to put in, take care of, and get new parts. Saving money is not just about the first price. Good hydraulic coupling products last longer and help systems work without stopping. This saves money over time.

Hydraulic coupling suppliers who make sure fluid moves well and does not leak help keep systems safe and working right.

Good hydraulic coupling manufacturers must follow tough rules. Many suppliers have ISO 9001 certification. This means they check quality in design, making, and service.

Suppliers often follow rules like AS, BCS, BS, DIN, EN, ISO, JIS, and SAE.

These rules make sure hydraulic couplings work well and make customers happy.

Picking iso certified coupling systems helps buyers feel sure about safety and quality. Suppliers who meet these rules often give high-quality hydraulic coupling products. These products help move fluids safely and work well in hard places.

Top hydraulic coupling manufacturers are known for new ideas and great help after buying.

Many suppliers use new designs, like flat-face couplers, to stop dirt and make care easier.

Some manufacturers help with everything, from picking products to helping after the sale, so customers have no trouble.

Custom solutions help with special needs and keep prices fair.

Manufacturers like Parker Hannifin and Gates Corporation always try to make better products. They add new hydraulic couplings and make them work better. Good help from hydraulic coupling suppliers means less waiting and always having parts when needed.

Picking a manufacturer that matches your project helps you get the best results, whether for factories, machines, or special hydraulic systems.

Company Profile:

Dongguan Tianying Mold Fitting Limited started in 2005. Now, it is a top supplier of hydraulic couplings and mold parts. They handle making, selling, and shipping, with a skilled team.

Product & Technical Advantages:

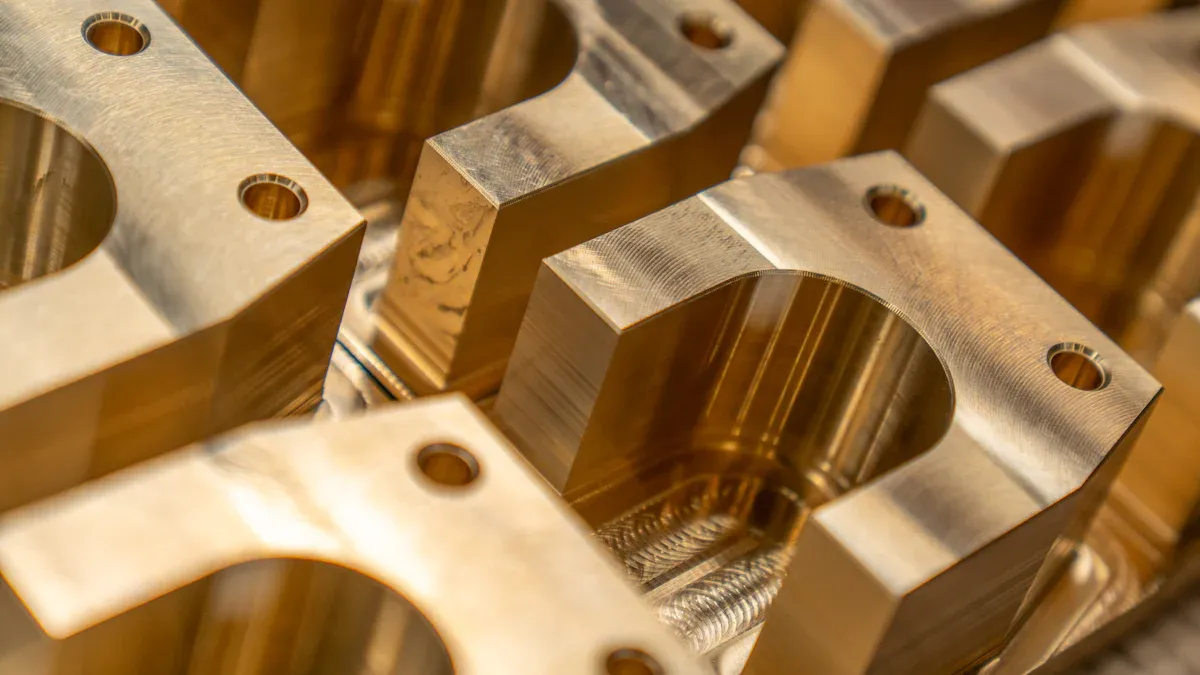

Tianying has many cooling parts, quick couplings, hydraulic quick couplings, pneumatic quick couplings, and custom fittings. Their products fit with big brands and do not leak. They can take high heat and last a long time.

Quality & Service Assurance:

A special team checks quality at every step, from start to finish. Tianying makes sure all parts match customer needs. They give technical help and custom options for mold makers.

Global Reach & Certifications:

Tianying sends high-quality hydraulic coupling products to China, Europe, East Asia, and North America. They always deliver on time and follow strict quality rules.

Location & Contact:

Dongguan, China

Website: https://www.ty-quickcoupling.com

Parker Hannifin is a top company in motion and control. They make many hydraulic couplings and fluid connectors. Parker Hannifin cares about the planet, safety, and saving energy.

They work on electric and green aviation, like the Alice plane.

CoolTherm helps manage heat and smart fans save energy.

Verdagent is a new fire agent, and they use hydrogen fuel.

Their e-brake and seals help cut down pollution in planes.

Eaton Corporation makes strong hydraulic couplings for many uses. They are leaders in smart power and care about the environment.

Manufacturer | Key Hydraulic Coupling Products | Company Focus / Strengths |

|---|---|---|

Eaton Corporation | Hose fittings, hydraulic adapters, accessories | Power management, innovation, electrification, digitalization |

Eaton’s couplings are used in farms, building, factories, and mines. They have many products and follow new digital trends.

Stucchi S.p.A. makes quick couplings for tough hydraulic jobs.

Feature | Details |

|---|---|

Product Range | Many choices for hard jobs |

Materials | Stainless steel, carbon steel, brass, and more |

Performance | High flow, high pressure, safe locks |

Innovations | VEP flat face coupling, multi-coupling plates |

Ease of Use | Quick connect and disconnect, no tools needed |

Custom Solutions | Special options for tricky setups |

Stucchi’s products help keep people safe and machines running.

CEJN AB is from Sweden and is known for safe hydraulic couplings. They follow ISO 14540 for high-pressure couplings. This lets their products work with other brands. CEJN gives safety tips and meets FDA rules for special hoses. Their focus on safety makes them trusted around the world.

Faster S.p.A. is a leader in quick-release couplings for many fields.

MultiSlide makes cleaner, smarter links for small diggers.

MultiFaster lets you connect many lines at once, saving time.

Spill-free couplings work well and stay safe under pressure.

Their R&D team makes custom castings for special needs.

Dixon Valve & Coupling has many hydraulic coupling products for the world.

They make hydraulic and air quick disconnects, hoses, and more.

Dixon tests products with force, steam, air, and tough conditions.

Training and values help them give good service.

Their modern factories and foundries keep supply steady.

Holmbury Ltd. is known for strong and reliable quick couplings. Their products are used in building and factories. Holmbury’s focus on lasting products and easy use makes them a top choice for hard jobs.

Kurt Hydraulics has many hydraulic couplings and hose choices. They focus on quality and good performance. Their products help with many transfer needs in factories and machines. Kurt Hydraulics stands out for making high-quality hydraulic coupling products.

SafeWay Hydraulics is known for strong and new quick couplers.

They made the first one hand push-to-connect quick coupling in 1969.

Their main products are for farms, factories, and heavy-duty jobs.

SafeWay’s couplings are used on tractors, loaders, and mining gear.

All products are made and put together in the USA.

Hydraulic couplings come in a few main types. Each type has a special job in moving fluids. Top manufacturers make these products to meet tough world rules. They also make sure they work in many places.

Quick couplings let people connect and disconnect lines fast. This helps workers save time when fixing or changing equipment. Most quick couplings follow ISO 7241 or ISO 16028 rules. These rules make sure brands work together and stay safe.

Push-pull quick couplings are good for jobs with lots of changes.

Snap type quick couplings use a ball lock to make strong, easy links.

Screw type quick couplings can take high pressure and shaking.

Wing nut quick couplings let you connect by hand, no tools needed.

Quick-release hydraulic couplings stop fluid from leaking out. They also keep dirt out. This helps keep systems clean and working well.

Quick couplings are important in mobile machines, farms, and factories. Their design stops leaks and keeps fluid transfer safe.

Flat face couplings are known for not leaking. These hydraulic couplings meet ISO 16028 rules. The flat face shape stops spills and keeps air out.

Flat face hydraulic couplings are best for clean or careful places.

They are safe and easy to clean.

Many companies use flat face couplings in building, mining, and hard jobs.

Flat face couplings also keep out dirt. This makes them a great pick for tough fluid transfer jobs.

Some jobs need custom hydraulic couplings. Manufacturers make these to fit special needs. Custom hydraulic couplings might use new materials or special shapes.

They can work with higher pressure or very hot and cold places.

Custom quick-release hydraulic couplings may let you connect under pressure.

These help with special jobs in molding, offshore, or high-tech work.

Custom hydraulic couplings often work better than normal ones. They help companies fix hard problems and follow strict safety rules.

Picking the right hydraulic coupling suppliers helps systems work well and last longer. The table below shows what to check when picking suppliers:

Criteria | What to Look For |

|---|---|

Quality | ISO certifications, warranty, and product samples |

Innovation | Investment in R&D, modern facilities, and adaptability |

Support | Responsive after-sales service and spare parts availability |

Practical Steps | Shortlist suppliers, request samples, and consider logistics |

Suppliers who care about quality, new ideas, and good help make sure fluid moves safely and systems keep working. People should talk to suppliers to learn more or get prices.

A hydraulic coupling joins two fluid lines together. It lets fluid move from one line to another. Many industries use hydraulic couplings to move power or control machines. These parts help machines run safely and do their jobs well.

Buyers should check if the products are good quality. They should see if the company has certifications and gives good support. It is smart to look for new ideas and if the company sells in many places. Reading what customers say can help a lot. Pick a manufacturer whose strengths match your project for the best results.

Certifications like ISO or SAE mean the company follows strict rules. These show buyers that the products are safe and work well. Certified products usually last longer and work better in hard jobs.

Yes. Many companies make custom hydraulic couplings. They design these for special sizes, materials, or uses. Custom solutions help with special projects and make systems work better.

Experts say to check couplings often. Look for leaks, damage, or wear. Change them if you see any problems. Good care keeps systems safe and stops long breaks.